The G&W Guide to… Ideal Site Investigations

Geoenvironmental • Geotechnical

Following on from our blogs on different Site Investigation techniques and equipment and their relative merits and drawbacks, you may be wondering what is an “ideal Site Investigation”?

The trouble with using the word “ideal” is the definition will be different for different geologies, so what follows is what we, know to be best practice that should be applied in every situation.

An initial Desk Study is vital

A Phase 1 Desk Study report forms the first stage of any construction project. The aim of the study is to provide a holistic overview of a site’s history and environmental setting, which may then influence the objectives of the Phase 2 Intrusive Site Investigation. This is achieved by careful examination of the following datasets:

A Phase 1 Desk Study report forms the first stage of any construction project. The aim of the study is to provide a holistic overview of a site’s history and environmental setting, which may then influence the objectives of the Phase 2 Intrusive Site Investigation. This is achieved by careful examination of the following datasets:

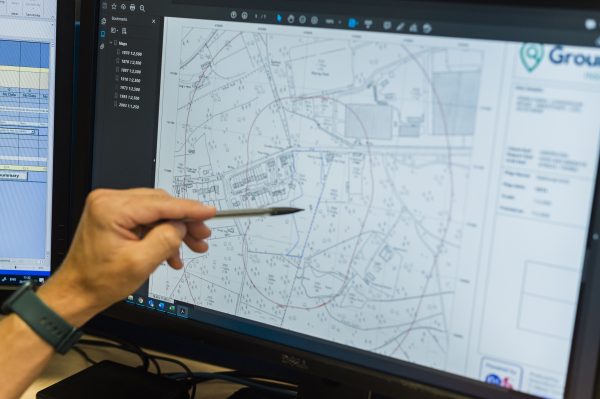

- Historical Ordnance Survey and aerial photograph examination to assess existing and former land-uses and potential contamination sources

- Flood risk potential by reference to Environment Agency records

- Solid and drift geology by reference to British Geological Survey mapping and borehole index records

- Groundwater vulnerability from Environment Agency classification of aquifer status

- Assessment of potential geological hazards such as subsidence, compressible deposits and dissolution features.

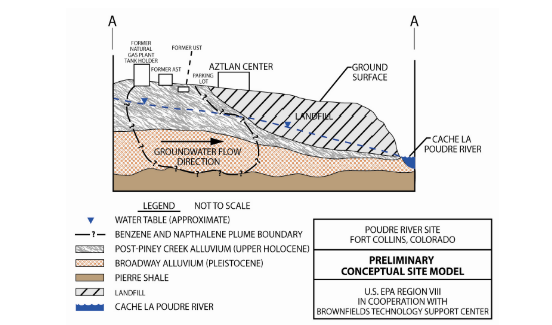

The first step of the Site Investigation is a robust Conceptual Site Model (CSM)

This is an absolute must, and links back to a previous blog we wrote on Site Investigation Theory Without a CSM you could be looking for Pears, when you wanted an Apple.

The second is that you want your best data where you have the most risk

This could be Class A (undisturbed) samples in clay where you highest column load is. It could be a machine excavated trial pit in chalk to get the best bearing capacity. Or it could be the deeper rotary/cable boreholes where the higher pile loads are anticipated.

Then we have to fill in the gaps

This is where we have quicker higher frequency data points filling in the gaps between the better data. This could be CPT boreholes filling in gaps between Rotary or Cable boreholes where chalk dissolution is noted. Equally it could be the other way round where CPT boreholes are highlighting areas of concern which require Rotary/Cable boreholes to be drilled so we can take samples for further analysis.

This is where we have quicker higher frequency data points filling in the gaps between the better data. This could be CPT boreholes filling in gaps between Rotary or Cable boreholes where chalk dissolution is noted. Equally it could be the other way round where CPT boreholes are highlighting areas of concern which require Rotary/Cable boreholes to be drilled so we can take samples for further analysis.

Another example could be dynamic probing between Rotary/Cable/Windowless sampler boreholes, or even trial pits and shear vane tests between WLS.

Filling in the gaps can be partially achieved by the use of geophysics in certain scenarios – cambering risks in the Hythe Formation perhaps?

The methods adopted to fill in the data gaps will be dependent on the CMS for the development. I.e. The geology, access and the proposed development. Obviously, the investigation could be phased.

Contamination Risk Assessment

What we have outlined above is from a geotechnical view point. Investigating for a Contamination Risk Assessment has a similar theme.

It all starts with a Desk Study, often called a Preliminary Risk Assessment. You do not want to be merrily thinking no remediation is required, when there are elevated levels of PFAS onsite, and the report failed to identify this as a contaminant of concern.

Then we have the tests in the areas of most concern (see the similarity)

This could be trial holes targeting underground tanks, or areas of burning or possible asbestos burial etc. Or it could be trial holes targeting the back garden areas of proposed houses and gas wells near to a landfill or where the deeper Made Ground might be encountered.

This could be trial holes targeting underground tanks, or areas of burning or possible asbestos burial etc. Or it could be trial holes targeting the back garden areas of proposed houses and gas wells near to a landfill or where the deeper Made Ground might be encountered.

These tests set the scene and allows the CSM to be developed further, with uncertainties identified.

Following this we need to try and remove as many of these uncertainties as possible, by filling in the gaps.

- Does the distribution of Benzo(a)pyrene or Lead in the Made Ground need further lateral and vertical distribution?

- Does the depth of Made Ground with respect to end-use need further clarification?

- Does the exposure of Lead to end-users need further assessment/clarification?

And finally

Collaboration is Key

Everything mentioned above can only be achieved through design by collaboration. What is meant by this is when Ground Engineers like ourselves, work in tandem with Architects, Technical Teams and Civil & Structural Engineers.

Attention to detail reduces cost in the long run

The ‘filling in the gaps’ bit, is what takes the most time, and some may question why it is necessary? The old saying “The Devil is in the Detail” is 100% applicable to Site Investigation best practice. This aspect of Site Investigation probably the most rewarding, because what it reveals almost always is the information that saves you money and time on the construction costs, and these savings will dwarf the cost of commissioning an “ideal Site Investigation”.