Forensic risk assessment gets to the root of a poisonous problem

14th May 2025

Geoenvironmental

Our Client

Preliminary-Assessment

The bedrock was Marlstone Rock Formation. The Marlstone Rock Formation is a sandy, shell-fragmental and ooidal ferruginous limestone, interbedded with ferruginous calcareous sandstone. Variable iron content is noted, but it’s understood that Arsenic within the Marlstone Rock Formation is a result of weathering of Iron rich sedimentary rocks. The levels of Arsenic can vary greatly from 23 – 753mg/kg.

A Detailed Detailed Quantitative Risk Assessment was required.

Our Challenge

Given the site was quite large and the previous investigation had noted high Arsenic concentrations our challenge was to pinpoint the locations and levels and design a remidiation strategy that avoided replacing all the Topsoil.

The Ground & Water Approach

Conceptual Site Model & Bio-accessibility

Unified Barge Method Bioaccessibility Testing was undertaken on samples recovered from an additional phase of the site works. This highlighted that on average only 3.6% of the Arsenic was bio-available within the Topsoil and 1.3% was bio-available in the Natural.

Based on a DQRA, using CLEA software, a SSAC of ~140mg/kg was determined for the proposed Allotments.

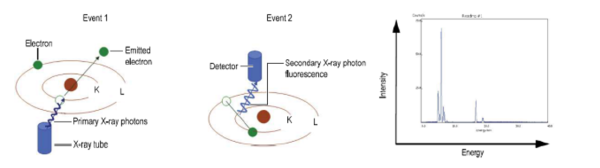

X-Ray Flourescence (XRF) Analysis

X-Ray Flourescence (XRF) Analysis

The next phase of the works was to understand exactly the vertical and lateral distribution of Arsenic within the soils onsite. The idea was to target each of the allotment plots and use X-Ray Flourescence to get mass in-situ Arsenic measurements. The measurements showed that, broadly, across the northern half of the allotments higher Arsenic concentrations were noted, in excess of the SSAC. In the southern half the concentrations were lower.

It transpired that this was due to the presence of a paler orange/brown Topsoil (averaging ~190mg/kg) instead of 65 – 70mg/kg.

The Outcome

Ground & Water’s approach meant this DQRA ultimately allowed a plot by plot remediation strategy to be adopted. This meant significantly less remediation being required than was first anticipated, saving the client money. The strategy adopted was to remove the pale orange brown Topsoil (which transpired had actually been imported) and replace it with certified clean. On other plots no remediation was necessary.