Get your validation conditions approved

Geoenvironmental • Regulation

‘Validation conditions approved’ is a phrase that both consultants and developers are likely never to tire of hearing. However, as Ground & Water engineer, Emily Murray highlights; reaching this stage can be a minefield, particularly within the Phase 4 validation process. Ground & Water is here to make that process as straightforward and easy as possible for you.

‘Validation conditions approved’ is a phrase that both consultants and developers are likely never to tire of hearing. However, as Ground & Water engineer, Emily Murray highlights; reaching this stage can be a minefield, particularly within the Phase 4 validation process. Ground & Water is here to make that process as straightforward and easy as possible for you.

There are two types of cover systems that can be employed – an engineered cover system and a simple cover system. An engineered cover system provides complete separation between potentially contaminated material that is to remain on site and the receptor. A simple cover system provides a reduction in the hazard to the receptor, as well as a growing medium for vegetation. This blog will focus on the suitability and design of simple cover systems.

A simple cover system is one option that can be used to remediate a site, but its suitability is highly dependent on a number of factors:

- The site has significant contamination, which poses an unacceptable risk to receptors. It would therefore require the excavation and removal of contaminated material, a greater thickness of cover or an engineered cover system.

- If the site has a high population of burrowing animals, there is a greater likelihood of contaminated material migrating to the surface due to animal activity. A physical barrier – i.e. crushed concrete – could minimise this.

- A site on a slope is at greater risk of failure due to gravity and the leaching of contaminants and a cover system is unlikely to be acceptable.

- The BRE “Cover Systems for Land Regeneration, Thickness Design of Cover Systems for Contaminated Land, BRE, March 2004”, allows for the design of cover systems to impacted soils where the concentration of determinands within the ground does not exceed any of the respective SGVs (Soil Guideline Values) or GACs (General Assessment Criteria) by more than six times. Therefore, the contaminant concentration also dictates whether a simple cover system can be adopted or whether an engineered system would be more appropriate.

- The determinand is also a deciding factor. For example, a cover system can only be used for asbestos if the asbestos risk assessment deems the risk is insignificant to the receptor.

Further design limitations can be seen within the guidance document BRE465 Cover Systems for Land Regeneration, March 2004.

If the site is deemed to be acceptable for the implementation of a simple cover system, there are various criteria that will need to be met to demonstrate no unacceptable risk to human health is present:

- The proposed source of the Topsoil needs to be identified and documentation needs to prove that it is suitable for intended use and in compliance with BS3882:2015 standards.

- Once the Topsoil is onsite, ideally before being placed, the imported Topsoil needs to be tested for various contaminants and evaluated against the most suitable land use scenario to ensure that no risk remains.

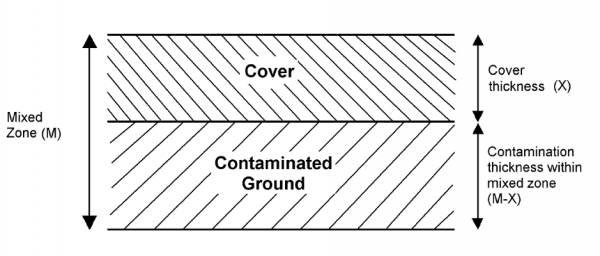

- The depth of the Topsoil is also crucial and will vary depending on the initial contaminant concentration, the contaminant itself and the target guideline value of the contaminant in the imported Topsoil. Computer models suggest that a 600mm mixed zone is the worst-case scenario for natural soils to naturally mix with the underlying contaminated soils. Ground & Water has the expertise and experience to ensure that this stage of the validation process is as straightforward as possible.

(diagram source- cover systems for land regeneration, BRE, 2004)

This stage can be tricky, so we have provided some top tips for the final stage of discharging planning conditions:

- Ideally test the imported Topsoil within the stockpile before placing within the garden areas at an appropriate sampling density. This will save the unwelcome cost of the removal and disposal of non-compliant Topsoil.

- Give yourself enough time to allow for setbacks if the Topsoil is not compliant, so that the all-important planning deadline is not missed.

- Ensure the consultant has as much information as possible to minimise setbacks. Photographs are a very useful resource in validation and verification.

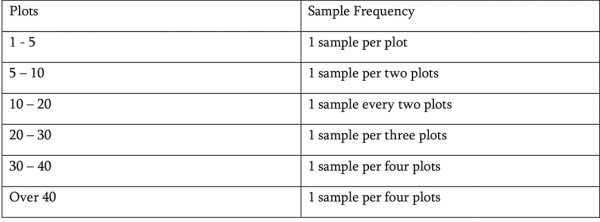

- What quantity of Topsoil needs to be imported? How many properties on the development? These questions all dictate the verification required. The NHBC has provided a handy guide for the testing requirement in relation to the number of plots.

Ground & Water will help you find a reputable source, provide independent verification and issue appropriate certifications of compliance for the imported soil; and help get the final planning conditions signed off.